Robot Systems

Current trends affecting manufacturing industries include labor shortage, harsh environment, short commodity cycles, small-volume and large variety orders, and frequent changeovers. In response, production lines need more smart, agile and flexible workstations.

- Avoid human touch

- Smart manufacturing

- Increase manufacturing yield

- Highly automated

- Reduce manpower

- Automated production tracking

- Smart service & manufacturing

- New technology & materials

- High efficiency & stable

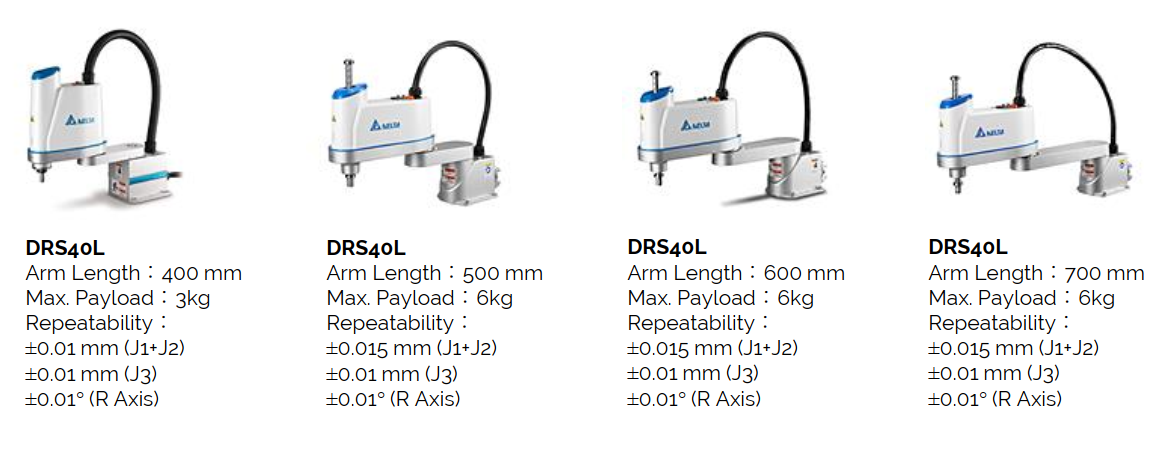

SCARA Robots

SCARA (Selective Compliance Assembly Robot Arm) robots are ideal for high-speed, high-precision applications. These robots offer excellent repeatability and are perfect for assembly, packaging, and material handling tasks in manufacturing environments.

Key features include:

- High-speed operation

- Excellent repeatability

- Compact design

- Easy programming

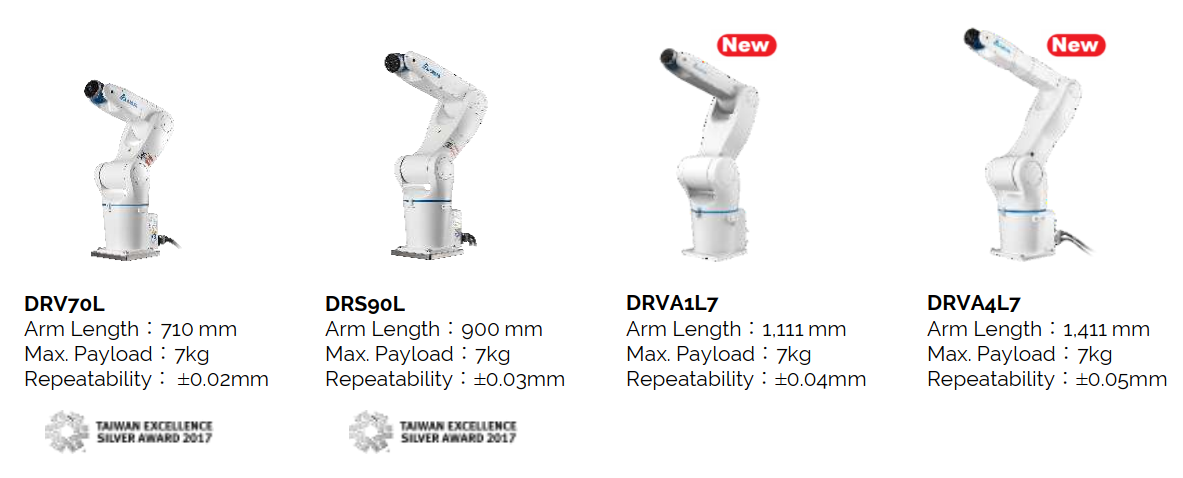

Articulated Robots

Articulated robots are versatile industrial robots with rotary joints that can range from simple two-joint structures to complex systems with 10 or more interacting joints. They are the most common type of industrial robot and are suitable for a wide range of applications.

Applications include:

- Welding and cutting

- Material handling

- Assembly operations

- Painting and coating

- Machine tending

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work safely alongside humans in shared workspaces. These robots are equipped with advanced safety features and sensors that allow them to detect and respond to human presence, making them ideal for applications where human-robot collaboration is essential.

Benefits of Cobots:

- Safe human-robot interaction

- Easy programming and setup

- Flexible deployment

- Cost-effective automation

Typical Applications:

- Quality inspection

- Pick and place operations

- Assembly assistance

- Packaging and palletizing

Robot Applications

Manufacturing

Automated assembly, welding, painting, and quality control in manufacturing environments.

Logistics

Material handling, packaging, sorting, and warehouse automation solutions.

Automotive

Body welding, painting, assembly, and quality inspection in automotive production.

Pharmaceutical

Sterile handling, packaging, and quality control in pharmaceutical manufacturing.

Food & Beverage

Food processing, packaging, and handling in hygienic environments.

Electronics

Precision assembly, testing, and handling of electronic components.

Why Choose Our Robotics Solutions?

- Comprehensive robotics portfolio

- Expert system integration

- Custom automation solutions

- Training and support services

- Proven track record

- 24/7 technical support

- Maintenance and spare parts

- ROI optimization